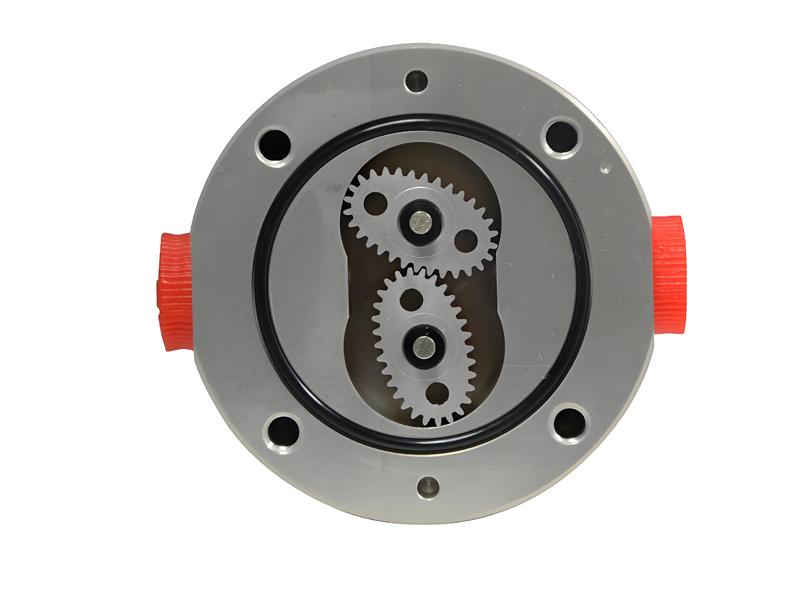

An oval gear flow meter is a type of positive displacement meter used to measure the flow of liquids. It works on a fairly straightforward principle involving two oval-shaped gears.

- Structure: The meter consists of two oval gears (often referred to as “rotors”) that mesh together within a chamber. These gears are housed inside a casing with inlet and outlet ports for the fluid.

- Fluid Entry: As the fluid enters the meter through the inlet port, it flows into the chamber where the oval gears are located.

- Gear Rotation: The fluid pressure forces the gears to rotate. As the gears turn, they create a series of small, fixed-volume pockets between their teeth and the chamber walls.

- Volume Measurement: Each time the gears complete a full rotation, a fixed volume of fluid has been displaced. The number of rotations directly correlates to the volume of fluid that has passed through the meter.

- Counting Mechanism: The rotational movement of the gears is detected by a sensor or is mechanically translated into a count by a register. This count is used to measure the total volume of fluid that has flowed through the meter.

- Output: The meter typically provides an output signal or display that indicates the flow rate or total volume of the fluid.

The key advantages of oval gear flow meters include their accuracy and the ability to measure a wide range of flow rates. They are particularly effective for measuring low to moderate flow rates and are often used in applications where precise volume measurement is crucial.